JetGuard® Sales

Get Tough Submersible Pumps Capable Of Handling Shotcrete

JetGuard® Hire

Reliable Dewatering Pump Hire for Your Mine Site

"The most significant barrier to the use of synthetic fibre has been the impact on the pumping systems. A submersible dewatering pump like JetGuard, which readily reduces the problems of synthetic fibre damaging pump impellers, is going to have a positive effect on production."

Professor Phil Dight

Professor Geotechnical Engineering,

Australian Centre for Geomechanics, University of WA

The Problem

The JetGuard Solution

You are operating in a tough environment already, tramp and Shotcrete fibre makes it even tougher.

Dewatering pump failure is slowing you down.

You need pumps that are going to last in the harshest conditions.

JetGuard® pumps are your solution.

Benefits

– Protect your dewatering infrastructure

– Reduce maintenance manpower you need

– Free up your electrical crew for higher priorities

– Keep Shotcrete fibre and tramp at sump site

JetGuard Delivers

– 25 Year Industry Experience

– Value For Money

– Continuous Improvement Through The PumpEng Way

Popular Articles

JetGuard Launches at PDAC in Canada

We are proud to be taking the innovative Australian designed JetGuard submersible dewatering pump to one of the world’s most important mining conventions. The Prospectors & Developers Association of Canada (PDAC) is an umbrella organisation representing a global membership of 7,500 members from the mineral exploration and development sector. The annual PDAC Convention is a…

JetGuard News at Underground Operators Conference 2020

We are excited about the upcoming Underground Operators Conference 2020 in Perth this March. Unlike the other industry events like MineX, Austmine and Worthy Parts (that focus more broadly on the mining industry), this trade show is focused on underground mining. It is a chance for all the different contractors and equipment providers servicing the…

Shotcrete Use In Ground Support For Underground Mining

This is an interview with Professor Phil Dight, Professor Geotechnical Engineering, Australian Centre for Geomechanics (ACG). The ACG is a joint venture between The University of Western Australia and the CSIRO and is a not-for-profit mining research centre. Professor Dight has worked with the ACG for 11 years. His areas of interests are open-pit mining,…

A Submersible Pump Designed To Deal With Shotcrete Fibre

Shotcrete Has Changed The Rules for Underground Mining

Most of the world's underground mines use Shotcrete to reinforce the walls of new tunnels. The use of fast-drying concrete makes the tunnels more stable, delivering safety and other benefits.

Shotcrete used in underground mining is frequently reinforced with small fibre to strengthen it.

The Shotcrete fibres can subsequently fall from the walls and mix with waste water.

The use of Shotcrete fibre has delivered major benefits for underground mining companies.

And it has also delivered some big, unintended consequences for dewatering operations.

How Shotcrete Fibre Can Cause Pumps to Fail

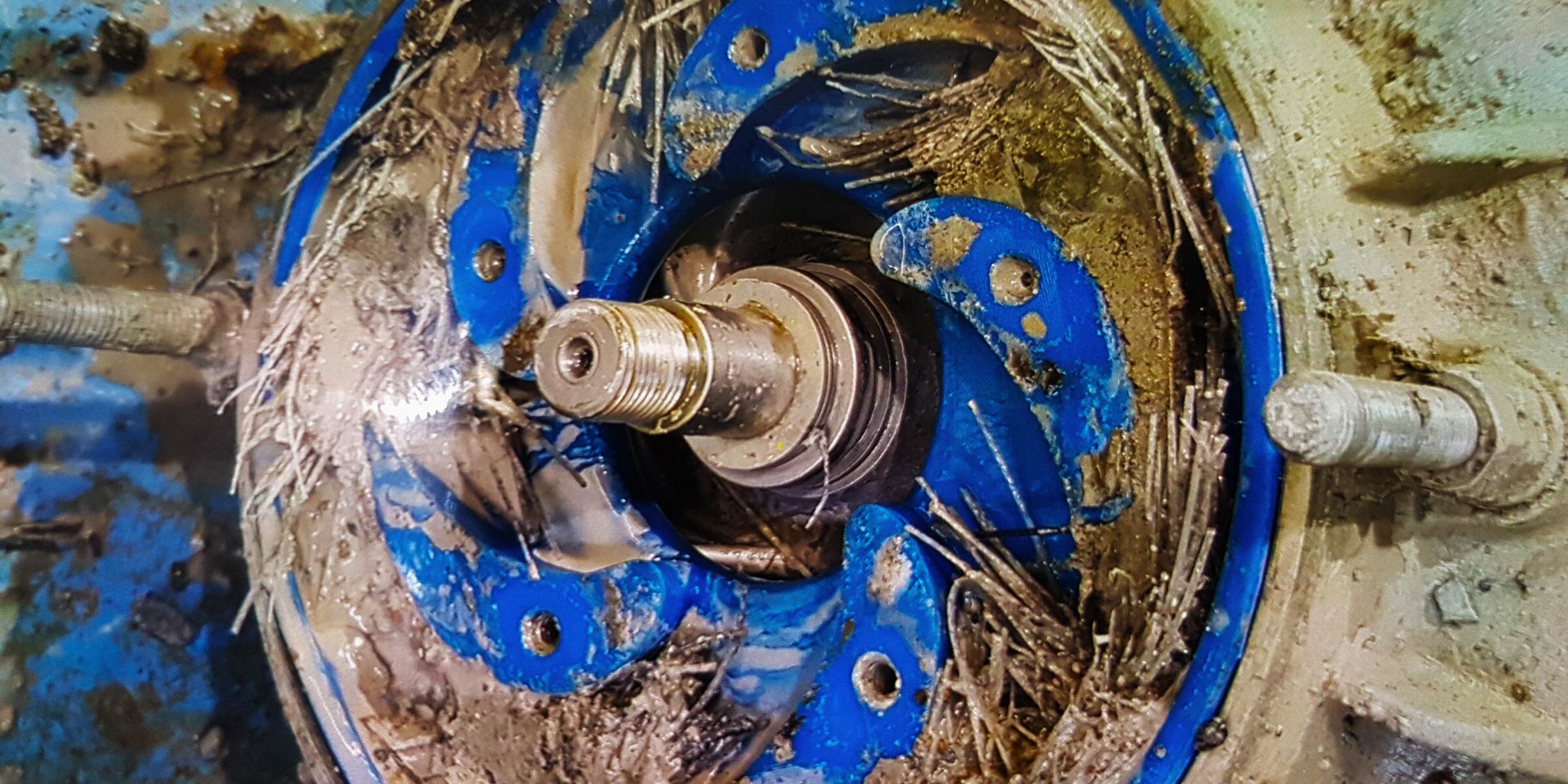

This picture shows a submersible pump where the impeller has failed due to Shotcrete fibre.

As water is pumped out of the mine, Shotcrete fibre is drawn into dewatering pumps and clogs them up.

Dewatering pump breakdown caused by Shotcrete delays mining production all over the world every day.

The Impact of Shotcrete Fibre on Mining Operations

When dewatering pumps are critical infrastructure, an entire mine can be forced to shut down because of dewatering pump failure driven by Shotcrete fibre.

The pump shown here was designed before Shotcrete was even invented. It wasn't designed for today's conditions.

The pump itself might have been located in a part of the mine that is difficult to access. This can make it hard to detect when a problem has occurred, and there are often substantial costs and risks associated with retrieving and repairing the pump to restore dewatering operations.

The Cost of Pump Failure

For many underground miners, Shotcrete fiber represents a major cause of pump failure and production delay.

And what is is the real cost of pump failure for a mining operation?

A multi-million dollar mining operation can be brought to a standstill because of one dewatering pump failure. The cost of the failure is not just measured by the cost of the replacement pump, but by the total lost production as well.

But production delays like this could be avoided if dewatering pumps are selected that have been designed for modern mining conditions.

The choice of a tougher pump can also reduce workplace hazards and boost efficiency.

JetGuard® is Protected

JetGuard has a defence-in-depth design to protect the pump from Shotcrete fibre.

Blocking Fibre From Getting Into the Pump

JetGuard is designed to block fibre from entering the pump.

JetGuard's patented design uses a hydraulic curtain to spray a curtain of water at the base of the pump.

In addition, JetGuard uses a bottom-mounted suction strainer, in contrast to older pump designs that use side-mounted suction strainers.

A lot of Shotcrete fibres float on the surface of a body of water. The combination of the hydraulic curtain and bottom-mounted suction strainer blocks many of the surface fibres that may otherwise get into the internal workings of the pump.

JetGuard® is Tough

JetGuard® has been built to be tough enough to withstand Shotcrete fibre for longer.

Managing Fibre That Gets Into the Pump

While JetGuard protects the pump from fibre, a reduced amount of fibre will still enter the pump.

JetGuard uses tough steel for internal components, avoiding lower-cost polyurethane and other plastic-based materials. Fibre chews up plastic, while it has far less impact on steel.

The JetGuard design incorporates a specially designed internal cutter plate. Any fibre that does get into the pump is chopped into small pieces to minimise impact. This reduces wear and tear on the pump, and allows for a clearer flow.

JetGuard® is Productive

JetGuard® is a new breed of submersible pump designed to keep you mining

Less Breakdowns More Production

What is the true cost when a submersible dewatering pump fails and causes mining operations to stop?

Think about it ... a multi-million dollar mining operation brought to a standstill because a single dewatering pump fails! Increasingly, the root cause of that pump failure is Shotcrete fibre.

Production delays like this can be avoided if the dewatering pumps you use are tough enough to handle modern mining conditions.

Tougher pumps can also help reduce workplace hazards and boost your efficiency.

It is true that the upfront cost of a JetGuard® pump is slightly more than its low-cost competitors. But when measured on total cost of ownership, JetGuard truly shines.