The new leader in underground dewatering submersibles with shotcrete management capability to help avoid clogged pumps.

It is a heavy-duty electro submersible pump with a high chrome impeller.

Underground mining, surface mining and general dewatering applications

JetGuard® is a submersible pump range for mining, construction and industrial dewatering.

The Right Pump For The Job

JetGuard®'s Three Pronged Approach To Handling Shotcrete Fibres

Keep Shotcrete out of the pump

Bottom Suction/Self Cleaning Strainer to minimise Shotcrete entering the pump.

Patented Hydraulic Barrier to keep Shotcrete away from the pump.

Minimise damage & allow pump to handle Shotcrete fibres

All metal wet end construction that won’t tear or lift.

Directional cutting assembly to reduce size of Shotcrete fibres to a size that the pump can handle.

Top/bottom suction impeller allows for easier flow path through pump and hydraulic balance.

Reduce breakdown & maintenance costs

Modular design across models to reduce part holdings.

“Quick strip” wet end & strainer reduces maintenance downtime.

Mechanical seal in low pressure area, removed from the fl uid path.

Non cartridge standard seal design protected by a rubber boot.

Dry run tolerance, water cooled/oil lubricated mechanical seal.

Jacketed to allow running on snore.

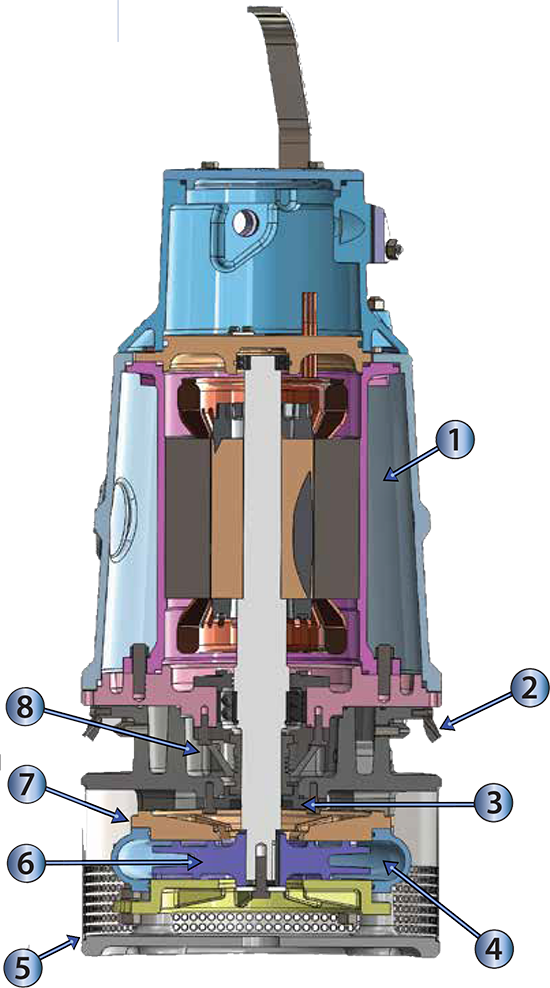

JetGuard® Unique Design Features

Hover over the circles to learn more.

Jacketed Stator - Snore Running Ability

- 1 of 8

Hydraulic Curtain - Shotcrete Fibre Barrier

- 2 of 8

Non Pressurised Seal - Longer Life

- 3 of 8

All Metal Wet End - Less Wear

- 4 of 8

Bottom Suction Strainer - Minimising Shotcrete Intake

- 5 of 8

Double Suction Impeller - E fficient Performance

- 6 of 8

Cutter Plate - Cuts Shot Fibres if Passed

- 7 of 8

Dual Seal Cooling - Water and Oil to Reduce Temperature

- 8 of 8